Sustainable Yarns

Sustainable Journey of Sutlej Textiles

"Sustainability has never been more relevant, there is much stronger demand for adopting sustainable materials, manufacturing processes so that the finished product has least negative impact on our environment. This desired transition to sustainable practices in textiles is also driven by consumer movement that has voiced preference for ‘sustainable garments’. At Sutlej Textiles, we are developing a range of ‘Sustainable Yarns’ using specialized fibres that are inherently eco-friendly. Many of these yarns have functional properties due to special attributes of these fibres and offer great value to customers."

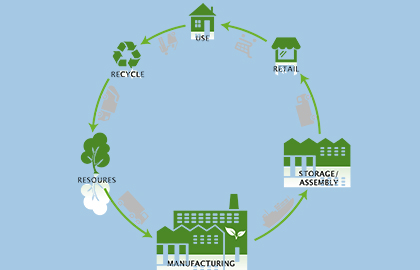

The concept of sustainable growth in textile and apparel industry can have many interpretations. However, its core meaning is adoption of practices that satisfies the present needs without compromising the environmental balance and to ensure that the future generations can have a sustainable living. The textile chain consumes a huge amount of water and energy, along with the use of various chemicals and harmful substances, with inadequate waste treatment

green cover

Ensuring abundant plantation of trees in the factory premises and our housing colonies to improve the Green Cover

energy efficient design

Continuous replacement of older-generation machines with more EnergyEfficient designs

water conservation

Zero-Liquid Discharge (ZLD) effluent treatment system with 90 percent water recovery

energy efficient lighting

Installation of EnergyEfficient lighting systems across the factory layout

renewable energy

Adopting Renewable Energy sources (Solar PV) to power our factories

recycled polyester plant

Set up a 120 tonnes-per-day Recycled Polyester fibre plant, than converts PET bottles into spun polyester fibre that are used mostly for captive consumption

Sustainable Manufacturing

Commitment towards Sustainablity

This desired transition to sustainable manufacturing practices is also driven by a consumer movement that has voiced preference for ‘sustainable garments’. The final product needs to have attributes of sustainability. Many international clothing brands are today leading the Sustainability Mission as they are best placed to drive consumer opinion and also back-link it to production & sourcing practices. Sustainability measures are applied to sourcing of fibres, production of yarn & fabric, the production of garments, packaging and even distribution.

Ecological Manufacturing

There is a dire need to adopt responsible methods of manufacturing, which do not pollute the environment, and control the reckless consumption of natural resources

Eco-friendly

At Sutlej Textiles, we are developing a range of Sustainable Yarns using specialized fibres that are inherently eco-friendly. Many of these yarns also have functional properties due to special attributes of these fibres and offer great value to customers

Certification

The product development and manufacturing practices supporting sustainability have earned Sutlej Textiles accreditations, which include Global Organic Textile Standards (GOTS), Global Recycled Standards (GRS), SA-8000 Certification (Ethically Correct Certified), Organic Content Standard (OCS-IN), OEKO-TEX (Standard 100).

Sustainable Yarns

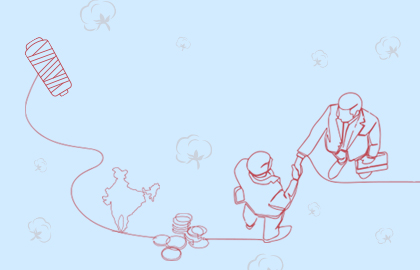

recycled polyester

Disposed PET bottles are converted into flakes which are finally turned into fibre in different denier polyester. Recycling PET bottles helps in reducing landfill.

recycled cotton

Recycled cotton can come from secondhand clothing or from textile waste or leftovers which are then spun into new yarns and fabrics

organic cotton

Organic cotton is grown using methods and materials that have a low impact on the environment. Organic cotton produce adhere to international standards such as BCI,Fair trade cotton

seacell

Yarn is produced using the Lyocell process, an innovative and eco-friendly production method. Production takes place in a closed loop with no chemicals released as waste.

smart cell

It uses recycled Zinc as its base which is melted and oxidisied into white power.This white power is combined with cellulosic fibre

cupro

Cupro is a regenerated cellulose fiber, soft, strong and silky, produced by treating cotton cellulose with cuprammonium salts.

hemp

The hemp plant is harvested during the early to mid-flowering stage. The hemp fibre are separated by retting ,which is process of decying pectin that binds the hemp fibre to the core of the stem. Once the fibre are separated they are spun together to produce long and continuous yarn

linen

It is made from a fibers of the flax plant. The fiber is very strong, absorbent, and dries faster than cotton. Garments made of linen are valued for being comfortable to wear in hot weather.

lenzing ecovero

Viscose fibers are derived from sustainable wood and pulp, coming from certified and controlled sources. fibers have been certified with the EU Ecolabel

lenzing refibra

The technology involves upcycling a substantial proportion of cotton scraps, in addition to wood pulp, where the raw material is transformed to produce new virgin yarn.

livaeco viscose

It is a natural fibre made from the regenerated cellulose fibre obtained from wood pulp. It is pro-planet and helps to save water, increases forest cover and reduces CO2 emission.

Modal

Modal is a type of yarn which is mixed with the silky type of fiber which is derived from the beech trees. Modal is generally more durable than regular rayon and feels softer, like cotton

tencel

It is a fiber made from the wood pulp of trees that are grown and replaced on specialized tree farms. It is very soft,breathable with wicking abilities.

excel

It is made mostly from forestry raw materials. It helps to achieve different hand feels in fabric

bamboo

Bamboo is soft, hypoallergenic, antibacterial yarn with amazing drape and luster. Bamboo yarn is made with bamboo grass that is harvested and distilled into cellulose that's then spun into yarn

bamboo charcoal

It is made by drying and burning of 5 or more year old Bamboo plants.The nano particles received from drying and burning is embedded into cotton fibres. It act as a insulator against cold weather

- We can provide the sustainable blends of the yarn by mixining the various fibre composition as per client requirements.

- We produce a high quality standards sustainable yarn.

- The company has well equipped most modern and state-of-art Quality Testing and development equipment, managed by a team of qualified and experienced professionals.

- We have USTER-5 Evenness Tester,HVI Spectrum,Tenso Jet 4, Advance Fibre Information System, Auto Despenser etc.