Green Thinking in Textiles: Insights on how today’s sustainability impacts tomorrow’s textiles

Using Renewable/Eco-Friendly Raw Materials

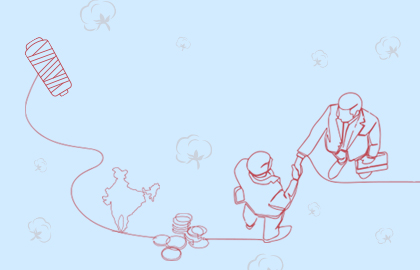

The ‘Go Green’ initiative, which is commonly discussed as part of industrialisation and automation, is neither hype nor an exaggeration. Climate change, global warming, pollution, and the threat from non-biodegradable materials & industrial wastes are real and with the advent of new technologies, businesses have to consciously make an effort to choose the right technologies, not only through the perspective of increasing productivity or convenience but also sustainability.

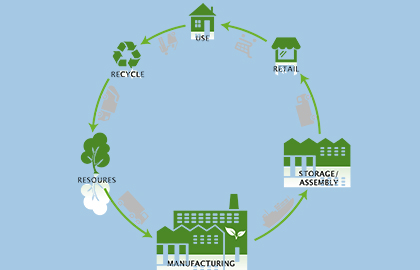

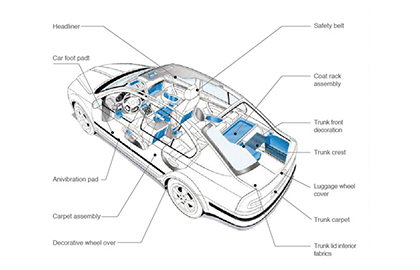

The textile industry is one of the largest industries in the world (approx. US$ 3 trillion), with an average contribution of approx. 2% of the GDP and employing more than 20 million people worldwide. Each process in the product lifecycle of textiles - be it yarn spinning, weaving, felting, knitting, braiding, etc. has a certain impact on the environment. When it comes to sustainability, this can be broken down to 5 different aspects:

Using Renewable/Eco-Friendly Raw Materials

Sustainability has been significantly attained in this aspect. Organic Cotton, Jute, Hemp, Bamboo, Wool, Sea Weed, Oil-based Fibres, Wood-based Cellulosic and other naturally-occurring materials are being constantly introduced by big and small brands. Brands like Nike and Prada have committed to the mission of using completely eco-friendly material and clothing by 2030.

Increasing Production Efficiency through Improved Processes

The focus of increasing efficiency through sustainable processes has led to manufacturers bringing in innovation to production lines, logistics, transportation, manufacturing, and even labour management.

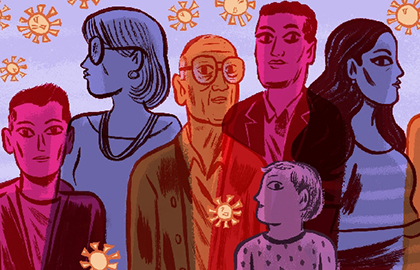

A good example of this is the ongoing pandemic and how the processes need to adapt to the transformed consumer psyche towards safety and precautions. Textile manufacturers are creating processes with minimal human interaction, focussing more on the packaging and looking to create sustainability in their processes to have long-term results.

Increasing the lifespan of clothing or recycling of existing textiles

A major part of the textiles, especially apparel and clothing, is the shortened lifespan of textiles usage. With easy availability through e-commerce and online shops, the higher purchasing power of the new customer-base, and heavy competition, the lifespan of a garment has reduced from the average of 3 years to 1 year in the past 5 years. But many brands are coming up which are completely focussed on providing sustainable clothing and recyclable clothing for sale.

UK-based TRAID is a clothes’ charity organisation, which encourages buyers to buy recycled or reused clothing which is sold through their 12 charity shops. Eco-spun (Welspun Inc.) and Patagonia are famous for selling fabrics made from recycled PET bottles. They can create 1 square metre of cloth from a two-litre PET bottle. K-sorb (Eco-sorb Intl.) and Barnhardt are other such companies that manufacture regenerated textiles and provide recycled products.

Proper treatment and disposal of byproducts and ancillary wastage

The textile industry is prone to a lot of ancillary wastage. The process of manufacturing had its own drawbacks, with a lot of water and air-pollution being caused, the use of harmful chemicals in the dyeing processes, and growing mounds of non-degradable synthetics. However, in recent times, the increased use of degradable/compostable materials has helped reduce these issues. Besides, government regulations and strict guidelines issued by governing bodies have helped to curb these problems drastically.

Bringing in Automation and Digitalisation in the right manner

Digitalisation is partly necessity and partly optional for textile manufacturing industries. Introduction of various technologies, data analytics, and artificial intelligence, not only in the ongoing processes but even in customer interactions, labour-management, and overall decision-making adds to the value brought about through digitalisation. This has drastically increased the scope of sustainability for the industry and it continues to be explored at a very rapid rate.

Using Renewable/Eco-Friendly Raw Materials

Sustainability has been significantly attained in this aspect. Organic Cotton, Jute, Hemp, Bamboo, Wool, Sea Weed, Oil-based Fibres, Wood-based Cellulosic and other naturally-occurring materials are being constantly introduced by big and small brands. Brands like Nike and Prada have committed to the mission of using completely eco-friendly material and clothing by 2030.

Increasing Production Efficiency through Improved Processes

The focus of increasing efficiency through sustainable processes has led to manufacturers bringing in innovation to production lines, logistics, transportation, manufacturing, and even labour management.

A good example of this is the ongoing pandemic and how the processes need to adapt to the transformed consumer psyche towards safety and precautions. Textile manufacturers are creating processes with minimal human interaction, focussing more on the packaging and looking to create sustainability in their processes to have long-term results.

Increasing the lifespan of clothing or recycling of existing textiles

A major part of the textiles, especially apparel and clothing, is the shortened lifespan of textiles usage. With easy availability through e-commerce and online shops, the higher purchasing power of the new customer-base, and heavy competition, the lifespan of a garment has reduced from the average of 3 years to 1 year in the past 5 years. But many brands are coming up which are completely focussed on providing sustainable clothing and recyclable clothing for sale.

UK-based TRAID is a clothes’ charity organisation, which encourages buyers to buy recycled or reused clothing which is sold through their 12 charity shops. Eco-spun (Welspun Inc.) and Patagonia are famous for selling fabrics made from recycled PET bottles. They can create 1 square metre of cloth from a two-litre PET bottle. K-sorb (Eco-sorb Intl.) and Barnhardt are other such companies that manufacture regenerated textiles and provide recycled products.

Proper treatment and disposal of byproducts and ancillary wastage

The textile industry is prone to a lot of ancillary wastage. The process of manufacturing had its own drawbacks, with a lot of water and air-pollution being caused, the use of harmful chemicals in the dyeing processes, and growing mounds of non-degradable synthetics. However, in recent times, the increased use of degradable/compostable materials has helped reduce these issues. Besides, government regulations and strict guidelines issued by governing bodies have helped to curb these problems drastically.

Bringing in Automation and Digitalisation in the right manner

Digitalisation is partly necessity and partly optional for textile manufacturing industries. Introduction of various technologies, data analytics, and artificial intelligence, not only in the ongoing processes but even in customer interactions, labour-management, and overall decision-making adds to the value brought about through digitalisation. This has drastically increased the scope of sustainability for the industry and it continues to be explored at a very rapid rate.

Steps to introduce green thinking:

The textile industry has consciously and dedicatedly made efforts to practice sustainability in their methods. While some brands have completely focussed on eco-friendly production or processes, many big and small brands are slowly converting their present practices to adapt sustainability. However, it might be a long way before the scales tip in favour of the earth’s sustenance.

On a broader level, companies can introduce different methods to adopt this change and begin somewhere.

Innovation

In recent times, all the latest innovations are primarily focussed on sustainability and saving the environment. If companies are not confined by financial, geographical, societal, or environmental constraints, they can turn towards implementing the latest innovations in the field to bring about sustainable changes:

- Implementing newer design strategies

- Turning towards newly-developed resources like eco-friendly dyes or fibres

- Introducing processes like exhaust piece dyeing, continuous dyeing, or cold-patch dyeing.

- Exploring waste-recycling options like composting, regeneration or non-woven methods

Awareness and educating the masses

Increasing awareness amongst masses, as well as educating the labour force or people involved in the manufacturing process is a great way to reduce wastage. In a McKinsey report, it was seen that 60% of customers are willing to pay extra for products that are made in an eco-friendly manner. Similarly, educating the labour force also increases their productivity and judgement, leading to long-term benefits.

Proactive approach through external governing bodies

Companies can take the help or be part of governing bodies like GOTS, OEKO-TEX, Sustainable Clothing Action Plan (SCAP) 2020 by Global Fashion Agenda, Sustainable Apparel Coalition, and so on, to proactively take measures for utilising resources, reducing pollution and proper treatment of wastage.

Creating the right environment (Environment Management Systems)

On the company level, businesses can ensure good practices and ethics to bring about a sustainable future in their business. This can include proper treatment of pollutants, replenishing naturally-occurring raw materials like wood through plantation drives, turning towards solar, wind, or other sources of non-polluting energies to run factories and so on.

Though the textile industry will boom considering the increased use of textiles and clothing in our day-to-day lives, it is necessary for the industry to proactively take steps towards sustainability. The green initiative is becoming more and more important as days go by. The modern-day business will run primarily on the ideology of sustainability and those who fail to recognise it may soon find it the hard way out.