Textiles & Apparel Industry - Measures to Improvement

Manufacturing Excellence

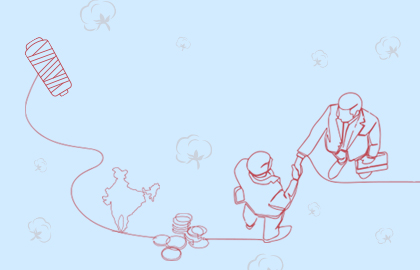

Textile industry in India can be dated back to the ancient Silk Route when traders and merchants from all over the world travelled to purchase from India’s rich supply of raw materials and fabrics. Little has changed over the centuries as India still remains the top exporters of textiles and apparel in the world. However, with growing competition from India’s neighbouring countries like Bangladesh and Vietnam, India needs to strengthen its position in the global textile and apparel market by making certain reforms in order to ensure its title status.

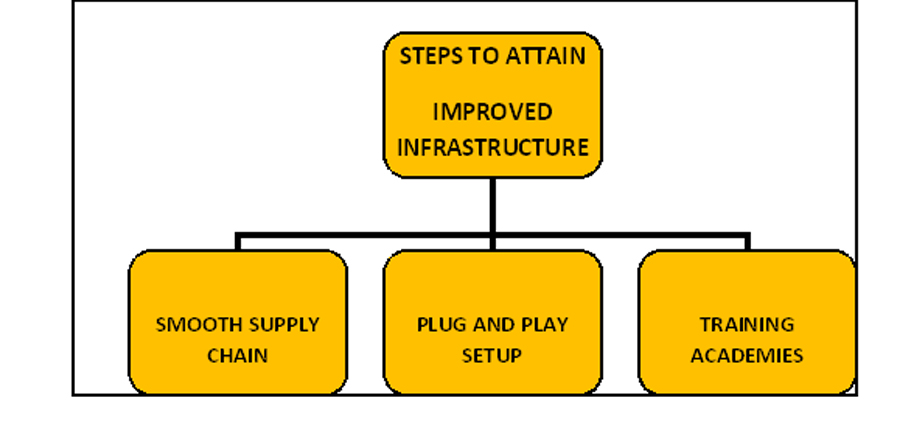

1. Infrastructure & Resources: Though India abounds in the existence of raw materials, the lack of systematic infrastructure poses a hindrance from truly achieving its full potential. A smooth operating supply chain with end-to-end solutions to ensure that sourced materials are smoothly transported to their destination is the need of the hour. Not only will this speed up the transit period but it will also ensure that the volume increases by minimising operational hurdles.

The same applies to the production of textiles and apparel. The launch of the Integrated Textile Parks by the Government of India is a worthy initiative towards this cause. Parks like Warangal’s Kakatiya Mega Textile Park can provide plug and play setup for domestic as well as international players to exploit the full potential and make operations smooth and systematic.

Skilled labour which is attuned to the latest developments in textile machinery like “Smart Machinery” is an important aspect which needs to be developed. While India abounds in manpower and relatively reasonable labour expenses with relaxed labour laws as compared to the first-world countries, the labourers are not updated. Setup of training academies by public-private sector to teach and train industry workers to the latest innovations in technology and hone their skills to ensure it meets the International standards of production is a gap which needs to be urgently addressed. Not only will this create top-grade skilled labour but it will also ensure uniformity in production across the country.

While India has an abundant source of raw materials like the coveted “Kasturi Cotton”, certain raw materials required for the production of textiles are not available here due to factors like climate, lack of minimum order quantity etc. The import duties on these materials, however, are exorbitant making production of these fabrics extremely expensive. The Government should look at easing these duties to provide equal opportunity for all fabrics to be produced and exported from India. Also, incentivisation like PLI can provide a big boost to manufacturers which in turn will aid growth in the textile industry.

2. Manufacturing Excellence: In order to be at par with the requirements of the first-world countries, India needs to strive to attain absolute manufacturing excellence. Mr. Suresh Khandelwal from Sutlej Textiles addressed this point in the recently conducted textile conference and aptly stated that Productivity and Quality are the two pillars of manufacturing which are interlinked and need to be consolidated to reach perfection.

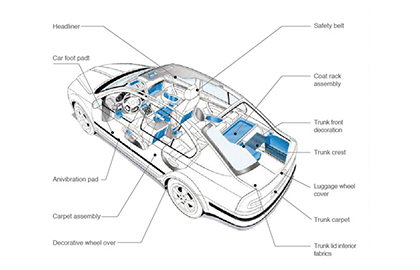

Achieving perfect productivity demands optimum use of the three Ms - Manpower, Machinery and Materials. Employment of skilled labour that adheres to international standards of quality is a necessity. For this purpose, awareness about quality standards needs to be spread across MSMEs and start-ups. Labour and management too need to be regularly updated with current company policies on quality control as well as the use of technology.

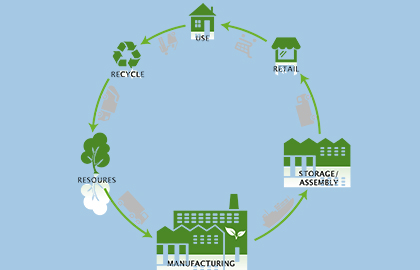

One of the key aspects of productivity is the sustainable practice of resources. Sustainability is not simply a practice; it has gradually become a requisite when catering to the global market. Consumers today are keen to know the journey of every product they purchase and if this journey is supported by sustainability, the product flies off the racks. Sustainable production of fibres and apparel hence is a demand which needs to be catered to at every stage of manufacturing. Indian textile players have adopted many sustainable methods but there is still scope for improvement. Bridging this gap will provide the thrust needed to catapult the Indian textile industry to the heights of supremacy.

Implementation of artificial intelligence in manufacturing as well as creating customer interface so that there is a clear understanding of what the customer desires will help curb wastage and hence reduce the cost of production. By using digitalisation to provide virtual sampling with 3D simulations, real-time samples can be approved hence saving lead time and improving productivity.

Consistency in quality is a key aspect which is often sidelined when manufacturing in bulk across a series of spread out consignments. Not only does this hamper credibility but it also prevents repeat orders due to lack of uniformity. The need to maintain quality across all units of manufacturing and adherence to international standards of quality is integral to the success of any product. Application of artificial intelligence to monitor, analyse and collect data will be helpful towards achieving this feat. The introduction of Intellectual Property Rights by the Indian Government will greatly enhance the quality and sanctity of the production. Constant scaling, upscaling and rescaling are integral towards quality maintenance as well.

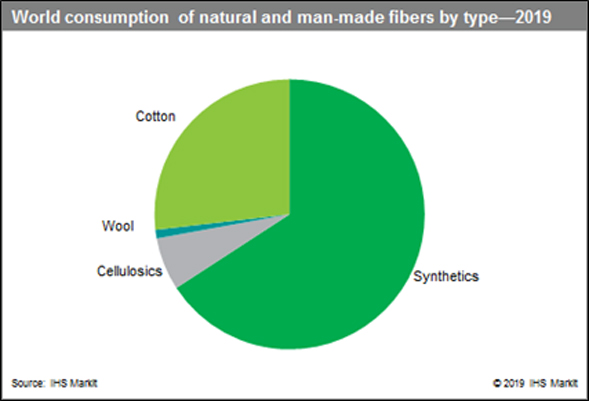

3. Man-made Textiles: As per the latest data, most countries are importing cotton textiles amounting to only 15% of their total requirements. The balance 85% constitutes man-made fibres and fabrics. Special fabrics hence are flavour of the new millennia and India needs to rise to cater to this demand. Worldwide consumers’ growing preference towards textile with characteristics of durability, better stain resistance, softness, and elasticity coupled with manufacturers’ ability to provide all such properties at lower costs is one of the key driving factors for the growth of the global synthetic fibre market.

Though India is the top producer of cotton and is world famous for its “Kasturi Cotton” and natural fibres, it is lagging behind countries like China as far as the production of man-made fibres go.

Organisations like Sutlej Textiles have risen to the occasion with their wide array of specialised and sustainable fabrics like a smart cell, hemp, recycled cotton and polyester and tencel to name a few. Not only are these fibres specially made using natural products under sustainable manufacturing; they provide the perfect amalgamation of man-made fibres with sustainable production. Many fabrics also provide additional features like dust resistance and fire retardance which is unique to them. These innovative measures to constantly upgrade fabrics and fibres add the extra glitter needed to make products special and exclusive.

India’s quest to attain the coveted crown of being the top manufacturer and exporter of textiles is now much closer to reality than ever before. India thrives in its abundance of raw materials and affordable labour. With the government launching initiatives like “Atmanirbhar Bharat”, “Make in India” and “Make for the World”, the plan has been put in motion. Setting up of “Plug and Play” Textile parks along with innovations by the great minds of Indian textile manufacturers has accelerated this motion further. It is now imperative that the opportunities presented by the world are combined with the utilities that the country has to offer and alchemised with modern practices and management to create the Golden Era for Indian Textiles.