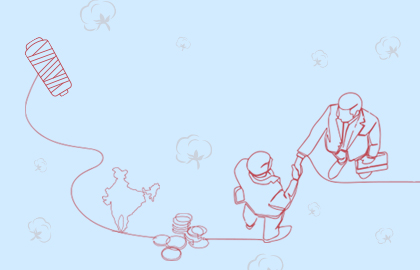

The art of sustainability in textiles through ‘unwasting’ Trends and remedies to master the art of waste management in the textile industry

Converting recycled waste materials to textiles or fabrics

Considering the larger schema of a sustainable environment, waste management has never been more important than it is today. The textile industry, though considered to be one of the major contributors to environmental waste, is one of the most proactive domains implementing new techniques and processes to manage waste and reduce environmental pollution. In recent times, the focus on waste management has increased rapidly, as the world is realising the effects, as well as the dire need, to save the environment through diligent actions.

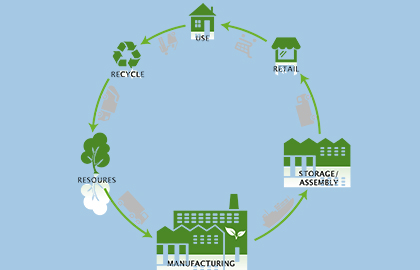

Broadly, the textile industry is addressing this issue through a trifold approach:

Converting recycled waste materials to textiles or fabrics

One of the major ways that textiles are helping in reducing pollution is by creating clothing and fabrics from waste materials like PET (polyethylene terephthalate). The process begins with melting the plastic into pellets and then firming chips. These chips are spun into threads and smaller fibre yarns, which later undergo stapling with different fibre varieties, as required, to create full-length recycled yarn. The recycling process not only helps in reducing plastic pollution in the world but also helps in reducing landfills, lesser use of virgin fibres, lower pollution emissions, and lesser use of harmful chemicals and dyes.

Brands like Fabric Monde, H&M Conscious, and Earth Polo Ralph Lauren are examples of some international brands which are turning plastic to fashion as part of their green initiatives.

Waste management techniques during textile manufacturing processes

The process of manufacturing fabrics is considered to be one of the most waste-potent processes. To give an example, it is estimated that for every fabric which is created, 15% of it is wasted during cutting. This is aside from the fact that it is a water-intensive process, as well as requiring extensive resources like electricity and other chemicals during the dyeing process or manufacturing of polyester fabrics. Digitalisation has played a lion’s role in helping reduce wastage during the manufacturing processes. Studies show that introducing automation has helped textile set-ups to become approx. 35% more efficient. The other aspect which has helped is the development of sustainable processes and innovative ways to recycle fabrics. Efforts to manufacture organic cotton reduce water usage, introduction to factories running on solar power and reduced uses of harmful chemicals have all added to waste management for a sustainable future.

Treatment of textile waste and recycled clothing

As the demand for clothing increases amongst the masses and various other sectors, the emergence of textile waste also rises. It is estimated that the USA alone produces more than 21 billion pounds of post-consumer textile waste (PCTW) every year. Out of it, 8% is reused as second-hand clothing, 10% is recycled, 25% is incinerated and the remaining 57% is sent to landfills. The Environment Protection Agency (EPA) and the Council for Textile Recycling, USA, has started an initiative to achieve 0% landfill by the year 2037. Parallel to it, efforts also need to be made to increase the practice of recycling and reusing clothing. Rarely used garments and clothing can be given a second life in two different ways:

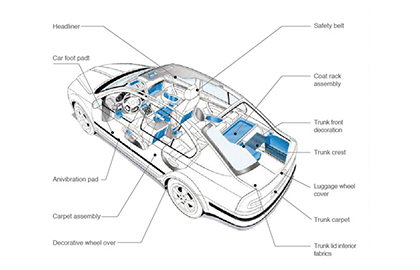

- Reusing them to creatively make quilts, cushions, accessories, bags, fillers in automobile and other industries, chic fashionwear, and so on

- Reselling them or donating them to charity so that the life of the garment increases. Many brands like thredUP have online stores to buy/sell second-hand garments, while others like Eileen Fisher have buy-back policies to help reduce wastage

Some of the major reasons for the wastage in the entire textile industry lifecycle, from crop production to scrapping, are the use of traditional methods, the magnitude of repetitive smaller wastages, and the ever-growing demands of the fashion-hungry consumers. While the industry focusses on coming up with sustainable answers to the first two points, the last point largely depends on the psyche of the customer. Only when the overall scenario shifts towards a conscious effort of managing and reducing wastage, will the negative effects subside. Though the industry has introduced this in recent years, it remains to be seen how long it will be before the transition begins to show notable results.