Sustainable Textile Manufacturing: Need of the Hour

TAGS WHICH SHOW SUSTAINABLE MANUFACTURING OF TEXTILES

The downward spiral of the state of our environment has forced humanity to realise that sustainability is the immediate need of the hour. All over the world, both governments and industries have been coupling to lead toward sustainable development. This year marks the fifth anniversary of the adoption of SDGs by The United Nations.

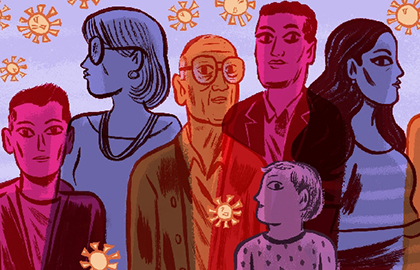

This holds even more importance as this is also the year of the pandemic. If there is one thing that this deadly virus has taught us, it is that we must try to understand and appreciate the limits to which humans can push nature, before it negatively impacts us. The balance between humans and nature needs to not only be maintained but also gradually restored to its pre-industrialisation era.

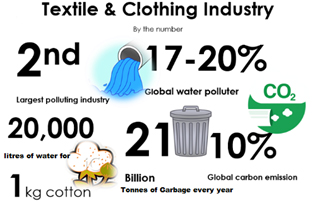

As aptly described by the U.N. -“Sustainable consumption and production are about doing more and better with less. It is also about decoupling economic growth from environmental degradation, increasing resource efficiency, and promoting sustainable lifestyles. “Unfortunately, Fashion has been labelled as one of the most polluting industries in the world. According to the Lensing Group, the world’s textile consumption was 95.6 million tonnes in 2015. Due to the numbers that the fashion industry generates, the impact on the environment can be truly deep and damaging.

The main environmental problems caused by the textile industry include water pollution, air pollution, and solid waste pollution.

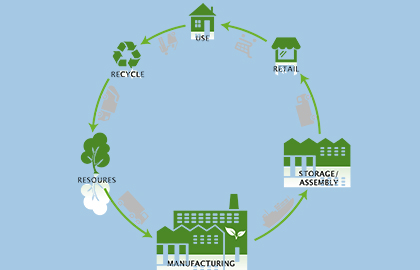

Practicing sustainability in textile manufacturing is hence the most important issue in the textile industry. Practices that fulfil the current needs of the manufacturing of textiles and at the same time do not lower the balance between industry and environment is called sustainable textile manufacturing.

Five major areas need to be addressed if we wish to make a move toward sustainable textile manufacturing. The remedies for these issues are as follows:

1. Use of lesser Chemicals: On average, the textile industry uses more than 8,000 chemicals to make the 400 billion m2 of fabric sold annually around the world. Many are toxic and persist in the environment. They include heavy-metal-rich dyes and fixing agents, bleaches, solvents, and detergents. These chemicals not only cause water and air pollution but also directly impact the health of the workers of the factory.

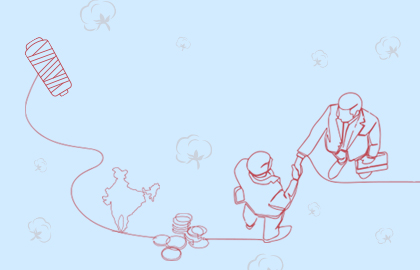

The use of chemicals starts from the nascent stage of crop production through the use of pesticides and herbicides and continues through the various phases of fabric-making in the processing, dyeing, and finishing steps. Around 60 to 80 percent of all fabric colorants are AZO dyes, which release chemicals when the fabric comes in contact with the skin and pose serious health hazards.

Though it is next to impossible to completely eliminate the use of chemicals, there are ways to minimise the impact of chemicals on pollution. The first and foremost task is to substitute harmful chemicals with relatively safer alternatives which have a low environmental impact. Textile chemical manufacturers like Archroma are an example of companies which provide sustainable chemicals for textile manufacturing. The use of natural dyes should replace the use of synthetic ones in the dyeing process. Organic growth of crops like cotton, silk, etc. can further help the cause and go a long way towards sustainable textile manufacturing. Textile manufacturers should participate in programmes such as Zero Discharge of Hazardous Chemicals (ZDHC),Buyers can also opt for sustainably sourced finished products that meet third-party certification standards such as the Global Organic Textile Standard (GOTS),Oeko-Tex® Standard 100, Bluesign® or the EU Eco label to create demand for textile which doesn’t impact the environment.

TAGS WHICH SHOW SUSTAINABLE MANUFACTURING OF TEXTILES

2. Minimising Air Pollution: Air pollution is caused at almost all stages of textile manufacturing like dyeing, printing, and finishing. Heat setting and colouring of fabrics are usually done at a temperature of 180 degrees which emits volumes of hazardous gases. Sustainable practice is to reuse the hot wastewater which creates heat of approximately 120-130 degrees. This will not only recycle water and chemicals but also minimise the use of energy, cause lesser air pollution -as well as save manpower costs by utilising lesser work hours.

3. Conservation of Water: On average, approximately 200 litres of water are required to produce 1 kg of textiles. So one can only imagine the countless litres of water which is required to fulfil the textile demand of the world. The wastewater released from these manufacturing plants contains salt, surfactants, ionic metals, and their metal complexes, toxic organic chemicals, biocides, and toxic anions to name a few pollutants. It is hence no surprise that 20% of the world’s wastewater is produced from textile manufacturers alone.

Wastewater management by recycling through the use of ETP (Effluent Treatment Plant) is the best way forward to help save the world from a global water crisis. Responsible companies like Sutlej Textiles have long ago installed ETPs across their factories which remove toxins from the wastewater and make it safe to be released or recycled. Implementation of such sustainable machinery not only reduces carbon footprints but also saves costs in the long run.

4. Renew Interest in Solar: The textile industry retains the deplorable record of the lowest efficiency in energy utilisation. About 34% of energy is consumed in spinning, 23% in weaving, 38% in chemical processing, and another 5% for miscellaneous purposes. Not only is gigantic volumes of energy consumed, it is also an extremely expensive process. Though various solutions have been tried by replacing electricity with alternative sources like biogas and wind, it is conversion to solar energy which has proved the most cost-effective, sustainable, and practical way forward. Fabric industries like Sutlej Textiles have paved the way for others by being among the frontrunners in the installation of solar power plants for captive consumption. A shift to solar energy by installing rooftop solar panels has dual benefits- it leads to sustainable textile manufacture by conserving and reusing energy and it contributes towards saving operational costs .

HOW SOLAR PANELS TAP REUSABLE ENERGY FROM THE SUN

5. Sustainable Machinery: It is now time to shift to new-age modern machinery which has been manufactured keeping environmental hazards in mind. These machineries not only minimise smoke emissions but they also use innovative methods that not only save energy but also prove cost-effective in the long run. Sutlej Textiles is a perfect example of textile manufacturers who have made the switch to green machinery.

Sustainable manufacturing of textiles is an attractive approach to tackle environmental problems and reduce carbon footprints. While the demand for fibres and fabrics continue to rise with the ever-growing population, it is the ethical duty of textile manufacturers to ensure that the environment is not impacted by it. Textile manufacturers need to abide by the four Rs to ensure that sustainability is practised –“Reduce, Reuse, Recycle and Rethink”.