A Nano Addition, A Revolutionary Difference Introduction to nanofabrics and the use of nanotechnology in textiles

Making of Nanofibres:

The evolution of textiles and modern-day yarns is focussed on 2 aspects. As one group of researchers aims towards creating environment-friendly, natural fibres, the other group is working towards improving functionalities and creating high-performance fabrics. One of the most recent developments in textiles pertaining to both these aspects is the introduction of nanotechnology in fibres.

Making of Nanofibres:

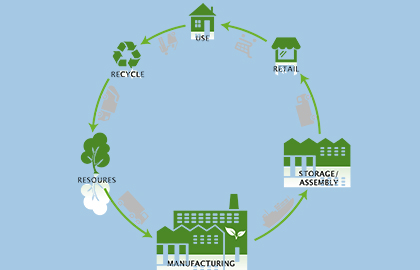

Nanoscience or nanotechnology has taken ‘intelligent fibres’ to a whole new level. Constant efforts are being made worldwide, to create fabrics using this recent era technology. Presently, it is being implemented in the following3 ways to create nanocomposite fibres:

- Integration of synthetic nanoparticles into the fibres

- Nanoparticles are added to nanoscale fibres, to create nanofibres

- Coating of fibres to create a thin layer of nanoparticles on the surface of the fabric

Application of Nanotextiles:

Nanofibres being one of the most versatile fabrics in the market today has immense uses across various domains. From medical textiles to industrial textiles, fashion, sports, wearable electronics, safety gear, and luxury apparel, every day new applications are being developed.

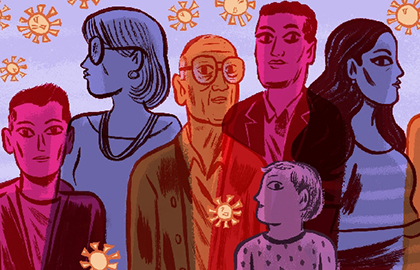

In Medical:

A great example of its use is in the creation of breathable PPE kits and face masks for protection against the ongoing COVID pandemic. Silver-infused nanoparticles coated on medical bandages are also used in medical procedures to help heal wounds faster.

In Fashion:

Another property of nanofabrics, being superhydrophobic, is implemented to create fabrics that are spill-proof, stain-resistant, and still breathable. Due to its anti-odour, anti-bacterial, and UV-protection properties, it is largely being used to manufacture fashion apparel, casual wear, shoes, bags, and so on.

In Defence:

Specially-designed nanofibres, called carbon nanotubes (or CNTs), due to its lightweight, yet heavy performance capability, is used in the manufacture of bulletproof vests (using carbon nanotubes), fire-resistant flame-suits, and other safety gears.

E-Textiles:

Nanotextiles, with their unique properties of conducting electric signals, are being explored to create electronic-based fabrics. Though e-textiles are in its nascent stage, it shows promising results. From heart-rate monitoring vests to electric sleeves, mobile-connected bags and wearable technologies, the scope for this fabric remains unending.

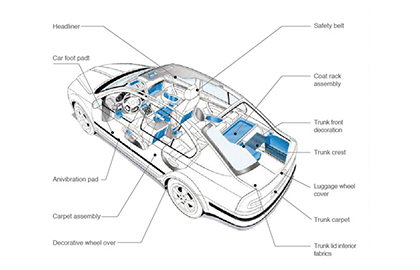

Industrial Textiles:

Creation of different kinds of filters, safety suits for workers, fire-resistant coating, conveyor belts, and so on… nanofibres are used at various measures in different industries.

The Road Ahead:

Nanotextiles are in a very nascent stage and there is still a world to be explored. The recent pandemic outbreak has further increased the necessity of such a safe, lightweight, and high-quality material on a mass level. The best part of this is that it can be applied to both naturals, as well as synthetic polymers.

Companies like Nanotex (USA) are dedicatedly working on the production of nanofibres, while Indian players like Sutlej remain keen to bring these fabrics to India on a larger scale. It only remains to be seen how rapidly this ‘wonder textile’ can penetrate our daily lives.