The growing prominence of Automobile Textiles

The growing prominence of Automobile Textiles

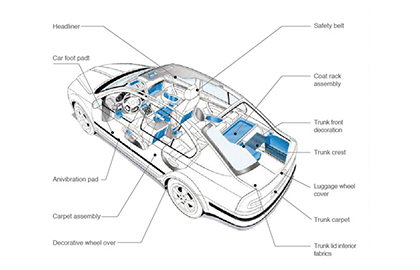

The automobile industry has remained as a growing market, that has led to cluster development of various ancillary industries. One of the beneficiaries, which has seen a steady growth in recent years, is automotive textiles, which are engineered fabrics developed as per the needed application in vehicles. Automobile textiles find applications in the manufacturing of, not just cars, but also in mass transit vehicles like buses, trains, heavy-duty trucks and even in defense vehicles.

Application in Car Manufacturing

According to GM experts, the annual consumption of textiles, including fibers, filaments, fabrics, and yarns in car manufacturing alone, is estimated to be over 4.5 lakh tonnes globally and steadily growing. On average, a single-car requires around 500 sq. ft. of textiles in making. A major share of this is knitted and woven fabrics, closely followed by non-woven fabrics and composites. These are a combination of various car parts and accessories, as required for 4 different reasons.

| Attribute | Application in Car Manufacturing | Type of Textiles used |

|---|---|---|

| Comfort | Seats | Cotton, Vinyl, Velvet, Leather |

| Safety | Seat Belts | Nylon Filament Yarns or Polyester Yarn |

| Air Bags | Nylon | |

| Body Cloth / Tarpaulin | Nylon, Cotton, Polyester or HDFE | |

| Tyre Cord Fabric | Nylon | |

| Functionality | Head Liners | Melted Polyurethane Foam |

| Insulation Felts | Polyester | |

| Sun Visors | Polyester Blend | |

| Noise Suppressors | Polyester Blend | |

| Filters | Cotton | |

| Aesthetics | Carpets | Polypropylene Fibres, Nylon |

With the advancements in technical textiles, the use of textiles is increasing in automobiles, the primary reason for it being to reduce the overall weight of the car. This has both performances, as well as environmental implications, as the weight of a car is directly proportional to its performance. A study by Lotus engineering, along with Toyota has shown that the overall body mass of a car can be minimised by almost 38% through an additional cost raised by a mere 3%. Carbon fibre is a largely used textile in this matter, which is high performing and lightweight. They are also believed to reduce carbon emissions considerably.

Applications in Aerospace and Railways

The aerospace and railway industries are turning from metal to composites for a large number of applications. Newly-developed polymeric materials with high thermal stability, like polyetherimide, polyethersulfone, and phenoxy are being tested out for its various uses. The primary challenge in creating such conductive yarns is combining these thermostable polymers with multi-walled carbon nanotubes (MWNT) by a process called melt spinning, to optimize its mechanical and electrical properties.

It is used on the airplane and railway engine applications, as well as in the development of high-performance space suits and data-suits.

The automobile textile industry is highly dominated by the European automobile market, closely followed by the US. GM report states that 70% growth of the automobile textile industry will be in 11 emerging markets - namely Russia, Brazil, South Korea, Poland, South Africa, China, Mexico, Thailand, Malaysia, Turkey, and India. With the rapid advancements in the field and the growing need for technologically-developed high-performing fabrics, many players will emerge to benefit from it. It is estimated that the growth of the industry in the next few years will be seen at 15% in China, 11 to 13% in India, and 5 to 6% in the US and European markets.

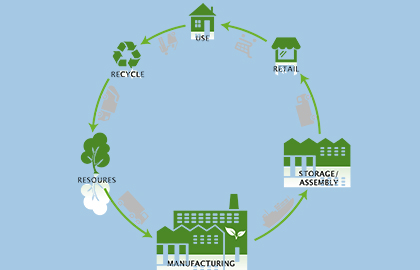

Considering the environmental implications of the same, it seems that the need for development of the automotive textile industry will soon gain precedence over the other areas of automobile manufacturing. Reduced carbon emissions, reduced greenhouse gas emissions and elimination of harmful materials in manufacturing are some of the biggest advantages of the industry as a whole.

With the daily advancements done by the automobile textile industry, it is anyone’s guess as to what can be expected next.

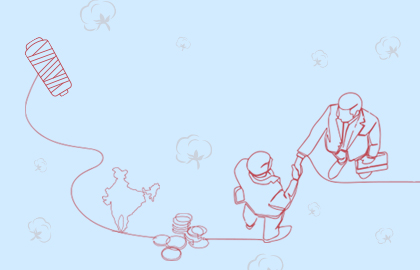

Product innovation and a legacy of committed quality manufacturing over several are the reasons for Sutlej having strong customer base. It’s the preferred brand for many leading textile manufacturers in USA, Portugal, Italy, Poland, Egypt, Bangladesh and Turkey. Sutlej Textiles consistently maintains quality across its manufacturing units and provides a seamless service support.

For more details about our products visit www.sutlejtextiles.com