Merging Textiles with Healthcare

The rise in demand for Kids Apparel post the lockdown

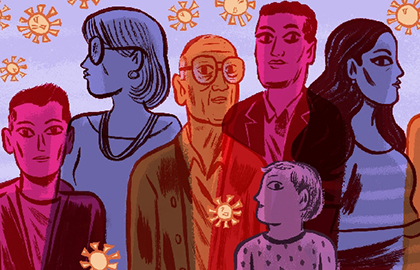

The emerging necessity of antimicrobial and antiviral textiles as a post-COVID demand

In the post-COVID era, facemasks and PPE kits have become as natural as any other uniform. But with the fear of the spread of disease and health concerns looming over the public, the demand for antiviral clothing and hygienic textiles, treated with various antimicrobial compounds, is going to be the long-term course. Studies have shown that the secondary source of contamination for airborne diseases, after transmission through coughing or sneezing, is its exchange through clothing, as microbes have shown to stay longer on contaminated clothes. This has urged the textile industry to work towards the treatment of clothes to make it resistant to all kinds of bacteria, viruses and microbes. It is estimated that the antimicrobial textile market will grow at a CAGR of 5.4%, from USD 9.5 billion in 2019, to USD 12.3 billion by 2024.

The Need across Various Industries

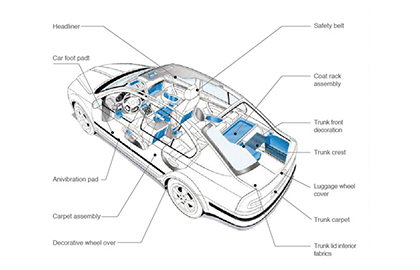

Though the medical and apparel industries are some of the largest beneficiaries of antimicrobial textiles, its applications exceed in other industries. Packaging, automobile, tourism, logistics, manufacturing and defence are a few sectors which drastically need to implement these textiles if they want to re-emerge from the pandemic. Commercial, Industrial and Home Textiles are amongst the most impacted textile segments looking for these ‘safe’ fabrics. A major part of the post-COVID era is to convince the end-users and customers regarding the safety of deliverables, where textiles is concerned. Using such anti-bacterial clothing, wherever required, will help customers to have a feeling of safety and hygiene.

The Evolution of Technology in Textiles

Though antimicrobial textiles are not a new thing, they are definitely the new trend. Ever since the pandemic situation, many technologies have been experimented and implemented to produce hygienic clothing. Companies have invested time and resources, along with emergence of alliances and partnerships, to create solutions. A few of the notable ones can be listed as follows:

- Nanocoating:

Nanocoatings have been proven to be 99.99% effective against viruses, bacteria, mold and other such harmful agents. This technology is being explored between nanocoating companies and global textile manufacturers to develop high-grade antiviral facemasks, breathable PPE kits and hazard suits, and other such applications of applied surface coatings. It is considered as one of the most effective ways of creating a safer, non-toxic, environment-friendly and easy-maintenance fabric, which can be water-repellent, self-cleansing and odour-inhibiting.

- Photoactive Dyes:

Treatment of fibres using photoactive dyes is one method which has shown promising results. Dyes which can generate single oxygen (the active agent responsible for nullifying the microbes and viruses) based on the intensity of light, are used for this purpose. Scientists are exploring this property, so that these dye coatings will be able to filter out viruses and make them inactive, based on their exposure to solar, incandescent or fluorescent lights. These fabrics, treated with photoactive dyes, have been proven to be hygienic and safe to use, even after 50 washes.

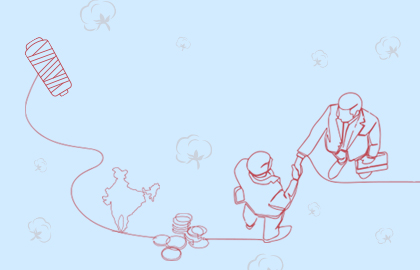

- HeiQ Viroblock NPJ03:

A newly-developed HeiQ Viroblock NPJ03 Swiss textile technology has been used by Indian textiles and yarn manufacturers, to create a highly efficient antiviral fabric, which has a wide range of apparel and home textile applications, including non-wovens like facemasks, air filters, uniforms, medical gowns, beddings, upholstery, carpets, etc. HeiQ Viroblock NPJ03 has been proven highly effective against the SARS-CoV-2 virus, with over 99.99% of contamination reduction. The HeiQ Viroblock NPJ03 technology, one of the first textile technologies proven to be an effective anti-COVID treatment consists of a special treatment of combining Advanced Silver and Vesicle Technology to create this innovative fabric.

- H+ Technology™:

Another advancement which has been curated between two Indian textile giants, Lenzing India and Ruby Mills, is the latest fabric treated with the H+ Technology™, to create a highly effective antifungal, antibacterial and antiviral fabric, which can be implemented in a wide range of pure, as well as blended fabrics. The technology provides enhanced protection, without any compromise on the fabric’s texture, breathability and use of comfort, for up to 30 washes.

The Global Outreach and Endeavour

Textile mills and manufacturers across the globe are in constant endeavor to introduce antiviral and ‘infection-free’ fabrics, and many have largely succeeded in doing so. In an attempt to promote hygienic and safe fabrics, many brands have come forward with a separate collection of antimicrobial textiles. ‘Fashionable Care’ brands like Liva (by Birla Cellulose), Travel Shield by Vardhaman Fabrics and Intellifabrix by Arvind Limited are just a few names of a long list. Considering the impact of these textiles in the global market, it was not a minute too soon.

Some of the most significant contributions by textile players worldwide are:

- Marseilles-based bio-tech company, Proneem, with the support of French-based company, Novachim, has developed a highly antiviral textile treatment method, called as Viral Stop™, which has proven to be extremely effective in neutralizing the SARS-CoV-2 virus on textile surfaces, with contamination reduction of more than 99.99%.

- PIECLEX, a carbon-neutral piezoelectric fabric, created between Japanese-based electronic company, Murata Manufacturing Co. Ltd, and Japanese textile giants, Teijin Frontier Co., uses piezoelectric technology to achieve antimicrobial properties without the use of any chemical agents.

- Other major players from across the globe, including Milliken & Company (USA), Trevira GmbH (Germany), Smith & Nephew PLC (UK), Sinterama (Italy), Thai Acrylic Fibre Co. Ltd (Thailand) and Carrington Textiles (UK), Unitika Ltd. (Japan), Lifethread LLC (USA) and many others, have manufactured antimicrobial fabrics which provide more than 95% of protection against bacteria and viruses, especially the dreaded SARS-CoV-2 virus.

The effect of the COVID-19 pandemic are here to stay for a long time and the way forward to emerge from this situation is going to require heavy innovation in the textile world. Though the necessary technology has been introduced to ensure revival, this field still remains open to be explored. Moving ahead, antimicrobial fabrics and textiles is going to be a necessity, which will be adapted across all industries, till the world becomes a safer place for the customers. In the meantime, what remains to be done is to win back the trust of the end-users that the yarns and textiles which they are using will keep them ‘safe’.